Forklift Truck Safety Signs-- Crucial Visual Cautions for Work Environment Safety

Forklift Truck Safety Signs-- Crucial Visual Cautions for Work Environment Safety

Blog Article

Trick Considerations for Designing Effective Forklift Safety And Security Indications

When developing efficient forklift safety and security indicators, it is essential to consider a number of essential factors that collectively ensure ideal exposure and clarity. Strategic positioning at eye degree and the use of resilient products like light weight aluminum or polycarbonate additional contribute to the durability and effectiveness of these indicators.

Color and Comparison

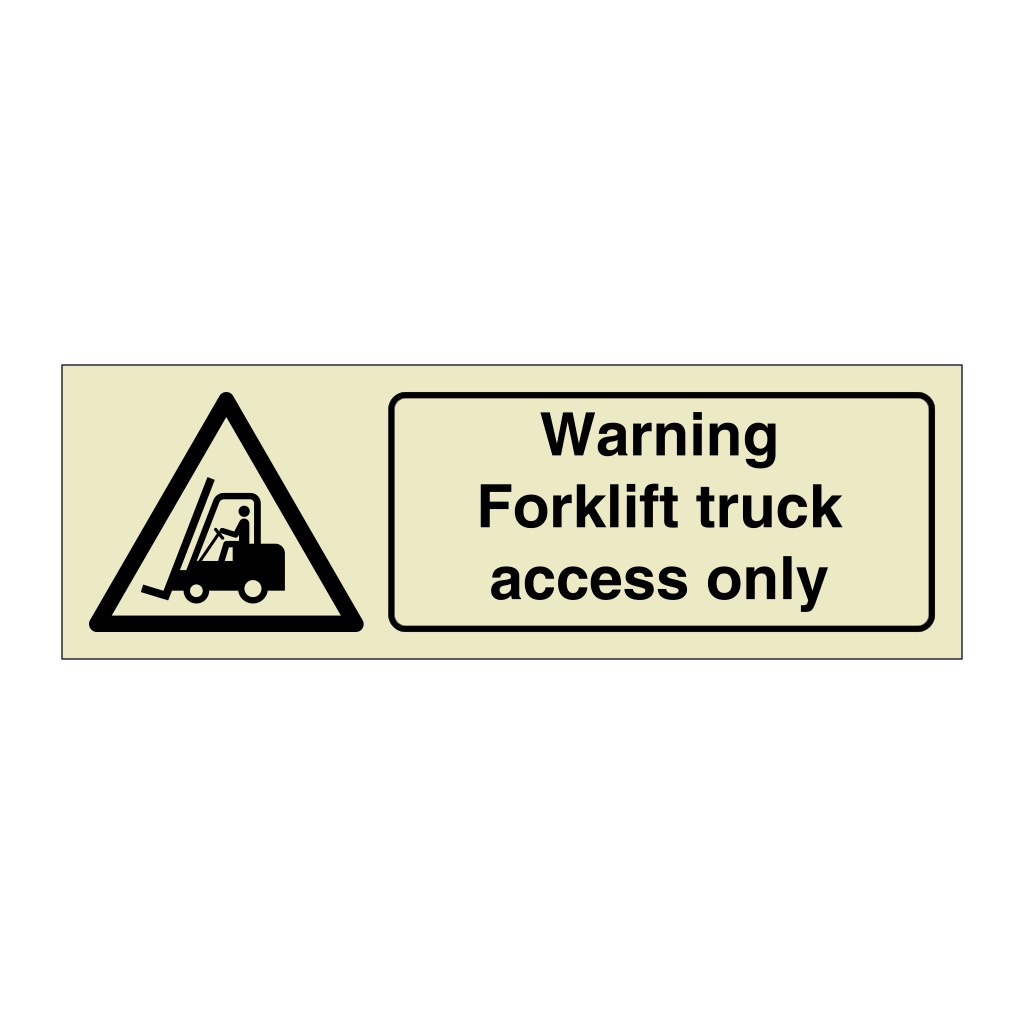

While designing forklift security indications, the choice of shade and contrast is critical to ensuring visibility and effectiveness. Shades are not merely visual elements; they offer important useful objectives by communicating specific messages rapidly and minimizing the risk of mishaps. The Occupational Safety And Security and Wellness Management (OSHA) and the American National Criteria Institute (ANSI) supply standards for making use of colors in safety indicators to systematize their meanings. As an example, red is generally utilized to signify instant threat, while yellow signifies warn.

Efficient contrast in between the background and the text or symbols on the sign is just as crucial. High contrast ensures that the sign is understandable from a range and in varying illumination conditions. For instance, black text on a yellow history or white message on a red history are combinations that attract attention prominently. In addition, the usage of reflective products can enhance visibility in low-light settings, which is often a factor to consider in warehouse setups where forklifts operate.

Making use of ideal color and comparison not only abides by regulative criteria but also plays an essential duty in keeping a safe workplace by ensuring clear communication of dangers and guidelines.

Font Dimension and Style

When making forklift safety and security signs, the option of typeface size and design is important for guaranteeing that the messages are legible and swiftly comprehended. The primary purpose is to boost readability, particularly in atmospheres where quick data processing is crucial. The typeface size must be huge sufficient to be read from a range, fitting differing sight problems and guaranteeing that employees can comprehend the sign without unnecessary strain.

A sans-serif typeface is commonly recommended for security indicators due to its tidy and simple appearance, which improves readability. Typefaces such as Arial, Helvetica, or Verdana are usually liked as they do not have the elaborate details that can cover crucial information. Consistency in font design throughout all security indications aids in developing an uniform and professional appearance, which further reinforces the significance of the messages being conveyed.

Additionally, emphasis can be achieved with calculated use bolding and capitalization. Keyword or phrases can be highlighted to draw immediate attention to necessary guidelines or warnings. Overuse of these strategies can result in visual mess, so it is essential to apply them sensibly. By meticulously selecting ideal font style dimensions and designs, forklift security indicators can successfully interact important safety info to all personnel.

Placement and Exposure

Making certain optimum placement and presence of forklift safety indications is critical in commercial settings. Proper indication placement can dramatically decrease the danger of mishaps and boost total workplace security. Signs should be placed at eye level to ensure they are easily visible by drivers and pedestrians. This typically means placing them between 4 and 6 feet from the ground, depending on the average height of the labor force.

Lights conditions likewise play an essential function in presence. Indications should be well-lit or made from reflective materials in dimly lit areas to ensure they are visible whatsoever times. The use of contrasting shades can further improve readability, especially in environments with differing light problems. By thoroughly thinking about these aspects, one can ensure that forklift safety indications are both effective and visible, therefore cultivating a safer working environment.

Material and Resilience

Picking the best materials for forklift safety and security indications is crucial to ensuring their longevity and effectiveness in commercial environments. Provided the rough conditions frequently experienced in warehouses and manufacturing facilities, the products selected should withstand a range of stress factors, consisting of temperature fluctuations, wetness, chemical exposure, and physical influences. Durable substrates such as light weight aluminum, high-density polyethylene (HDPE), and polycarbonate are preferred selections as a result of their resistance to these components.

Light weight aluminum is renowned for its toughness and deterioration resistance, making it an exceptional selection for both indoor and outside applications. HDPE, on the other hand, supplies phenomenal effect resistance and can endure prolonged direct exposure to extreme chemicals without deteriorating. Polycarbonate, recognized forklift safety signs for its high impact strength and clarity, is typically made use of where presence and sturdiness are critical.

Just as essential is the kind of printing utilized on the signs. UV-resistant inks and safety finishes can substantially enhance the lifespan of the signs by preventing fading and wear brought on by extended exposure to sunshine and other ecological elements. Laminated or screen-printed surface areas supply extra layers of defense, guaranteeing that the essential safety info stays understandable over time.

Investing in high-grade materials and durable production processes not just expands the life of forklift safety indications however likewise enhances a society of security within the office.

Conformity With Laws

Abiding by regulative criteria is extremely important in the style and release of forklift safety and security indicators. Conformity guarantees that the signs are not only effective in communicating crucial safety information yet additionally fulfill lawful responsibilities, consequently minimizing possible responsibilities. Different organizations, such as the Occupational Safety And Security and Wellness Management (OSHA) in the USA, supply clear standards on the specs of safety indicators, including color systems, text dimension, and the incorporation of universally identified icons.

To follow these laws, it is necessary to perform a comprehensive evaluation of applicable standards. As an example, OSHA mandates that security signs need to show up from a distance and include certain shades: red for danger, yellow for care, and eco-friendly for safety and security instructions. Additionally, adhering to the American National Specification Institute (ANSI) Z535 collection can further enhance the effectiveness of the indicators by systematizing the style aspects.

In addition, routine audits and updates of security indications need to be performed to guarantee ongoing compliance with any kind of changes in laws. Involving with certified safety and security specialists during the design stage can likewise be advantageous in making sure that all governing requirements are fulfilled, which the indications offer their desired function effectively.

Verdict

Creating reliable forklift safety and security indicators calls for careful interest to color comparison, typeface dimension, and style to make certain optimum presence and readability. Strategic placement at eye level in high-traffic areas enhances understanding, while using durable products makes sure durability in various ecological conditions. Adherence to OSHA and ANSI guidelines systematizes safety messages, and integrating reflective products enhances presence in low-light circumstances. These factors to consider collectively add to a safer working atmosphere.

Report this page